When it comes to tpe overmolding bonding and substrate considerations, there are several important factors that need to be taken into account. This article will explore these considerations in detail, providing valuable insights for businesses in the industry.

The Importance of TPE Overmolding Bonding and Substrate Considerations

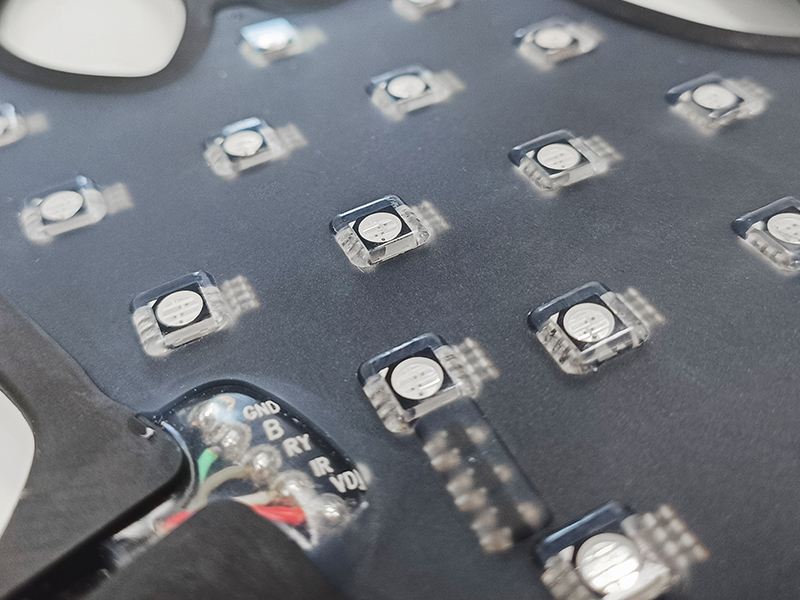

TPE overmolding is a process that involves molding a thermoplastic elastomer (TPE) onto a substrate material. The bond between the TPE and the substrate plays a crucial role in determining the overall performance and durability of the final product. Therefore, careful consideration must be given to various factors during this process.

JVTECH: A Leader in TPE Overmolding Bonding Solutions

One company at the forefront of providing innovative solutions for TPE overmolding bonding is JVTECH. With their extensive experience and expertise in this field, they have developed cutting-edge techniques that ensure strong adhesion between TPE materials and substrates.

By utilizing advanced surface treatment methods such as plasma or chemical etching, JVTECH prepares substrates for optimal bonding with TPE materials. Their precise control over processing parameters ensures consistent results, resulting in high-quality products with excellent bond strength.

The Advantages of 2K Molding Techniques

In addition to traditional single-shot overmolding processes, 2k molding has gained popularity due to its numerous advantages. This technique involves using two different materials injected sequentially into a mold cavity to create complex parts with varying properties.

With 2K molding, manufacturers can achieve superior design flexibility by combining different colors or hardness levels within a single component. Furthermore, this technique eliminates secondary assembly steps while reducing material waste, making it a cost-effective solution for many applications.

When considering TPE overmolding bonding and substrate considerations, 2K molding offers an additional layer of complexity. However, with the right expertise and equipment, companies like JVTECH can successfully navigate these challenges to deliver exceptional results.

Conclusion

TPE overmolding bonding and substrate considerations are crucial aspects that directly impact the quality and performance of products. By partnering with industry leaders like JVTECH who specialize in providing innovative solutions for TPE overmolding bonding, businesses can ensure strong adhesion between materials and substrates.

Incorporating advanced techniques such as 2K molding further enhances design flexibility while reducing costs. With careful attention to these considerations, manufacturers can produce high-quality products that meet customer expectations in terms of durability and functionality.